현재 위치

홈상품상세정보

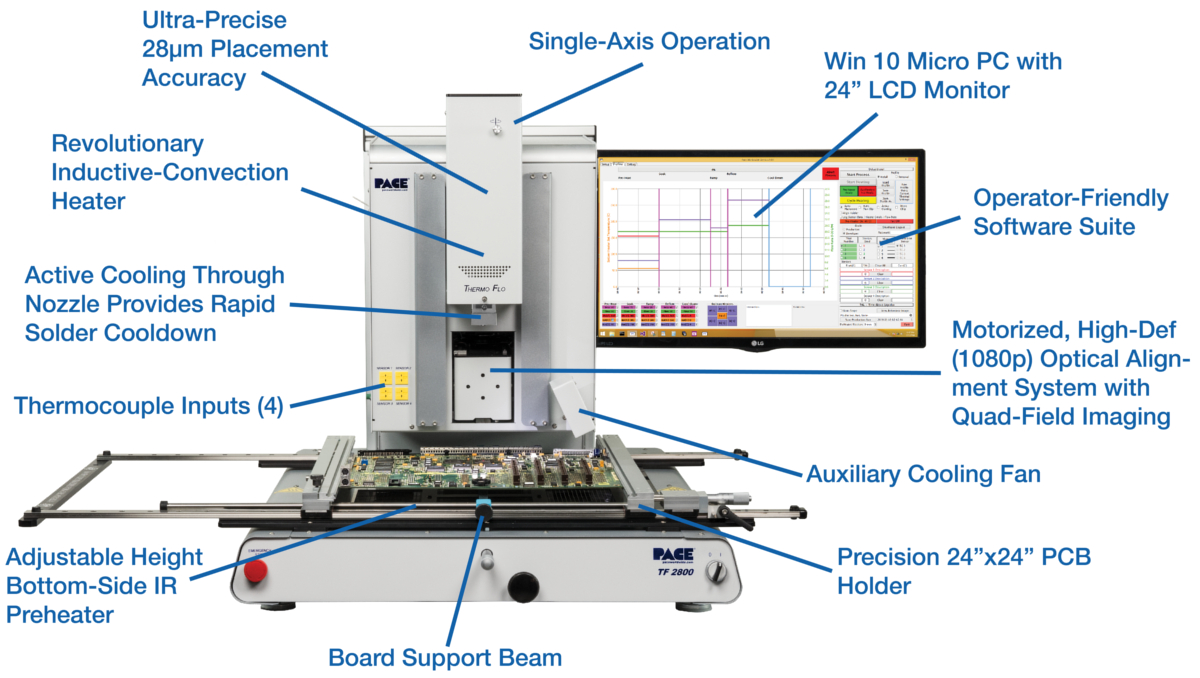

- FeaturesUltra-Precise 28µm Placement AccuracyRevolutionary Inductive-Convection HeaterActive Cooling Through Nozzle Provides Rapid Solder Cooldown4 Thermocouple InputsAdjustable Height Bottom-Side IR PreheaterBoard Support BeamPrecision 24" x 24" PCB HolderAuxiliary Cooling FanMotorized, High-Def (1080p) Optical Alignment System with Quad-Field ImagingSingle-Axis OperationWindows 10 Micro PC with 24" LCB MonitorOperator-Friendly Software SuiteMade in the USA

- SpecificationsPower Requirements120 VAC, 50-60Hz (requires 20 A supply)|| 230 VAC, 50-60Hz (requires 10 A supply); 1600W maximumDimensions737mm (29") H x 1118mm (44") W x 965mm (38") DWeight (Without Computer)90kg (200lbs)Top-side HeaterInductive-Convection Heater, 300 WattsBottom Side HeaterMedium/Long wave IR, 1900 Watts; 405mm (16") x 405mm (16") || (1 x 1000 Watts & 6 x 150 Watts)Bottom Heater Adjustable HeightCan be raised up to 38mm (1.5") closer to the PCBActive Cooling CapabilityOffers swift, yet controlled component/PCB cooling, directly through the nozzleHigh Sensitivity Vacuum PickCounterweight balanced with an optical sensor and precision high temperature linear ball bearings (includes 7 picks)Precision Placement CapabilityPlacement system utilizes a stepper motor and position encoding for precise movementPlacement Accuracy28μm (.0011") accuracyIntegrated Board Support Beam2 standard supports, 1 x support wand & 1 x fixed center height adjustment, prevents PCBs from sagging or warping during rework and is extremely adjustable to clear parts on bottom of PCB.Temperature Setting RangeTop Heater: 100˚ to 328˚C (212˚ - 624˚F); Bottom Heater: 100˚ to 221˚C (212˚ - 430˚F)Max PCB SizeMaximum: 610mm x 610mm (24" x 24"); Minimum: N/A arms close down completelyMax/Min Component SizeMaximum: 65mm (2.5") x 65mm (2.5"); Minimum: 1mm Sq.Thermocouple InputsFour (4) thermocouple inputs insure accurate profile development and real-time monitoring (includes 2 K-type thermocouples)High Definition Optical AlignmentVision Overlay System (VOS) with High Definition 1080p color cameraVision Overlay System (VOS)Contains integrated frame grabber and dichroic beam-splitting prism with independantly controlled LED lightingVOS Zoom CapabilityUp to 240x zoom capability, with Stable Zoom and image stabilizationQuad-Field ImagingAllows up to four opposite corners of a large component (and its pads) to be viewed under higher magnificationSingle Axis OperationAll operations are complete in a single axis, eliminating risk of component movement after placement/reflowAuxiliary Cooling FanStandardSoftwareIntuitive, user-friendly, Windows software guides operators through profile development and executionComputer SystemWindows 10 PC, with wireless mouse and keyboardVideo Monitor607mm (24") wide screen flat panel monitor (includes Monitor Arm Mounting Kit)Maximum AirflowSelf contained pump, PC controlled, adjustable up to 30 SLPMComponent NestsTwo (2) removable and adjustable Component Nests provided for perfect centering of components, in preparation for vacuum pick-up/placement. Unique component holding system for parts under 5mm Sq.Heat Focusing, Vented NozzlesOver 90 nozzles availableFlux Application PlateIncluded; allows for automated flux dippingStencils/Solder Paste ApplicationOver 145 stencil kits are optionally available (requires Universal Bracket Kit) and are integrated into the installation processPV-65 Pik-Vac Vacuum WandIncluded; provides a manual vacuum pick-up capability for handling SMDs, with 15 minute auto-off featureWarrantyOne Year Limited Warranty

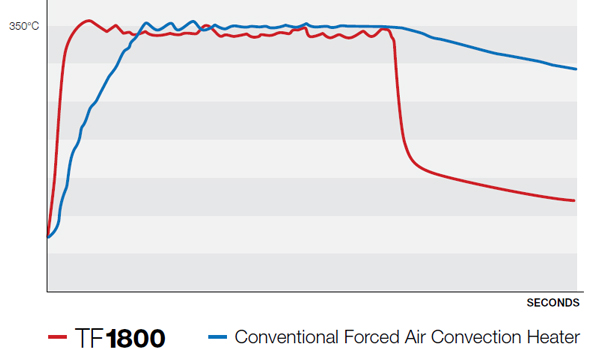

Top-Side Heater: Fast Heat Up - Rapid Cool Down

PACE’s Inductive-Convection Heater easily outperforms competitive heaters which utilize standard forced air convection technology, achieving target temperature instantaneously, about 4x faster than competitive heaters. Unlike conventional heaters, the TF 2800 immediately drops to temperatures well below solder melt when the heater is de-energized (results shown for TF 1800 Heater).

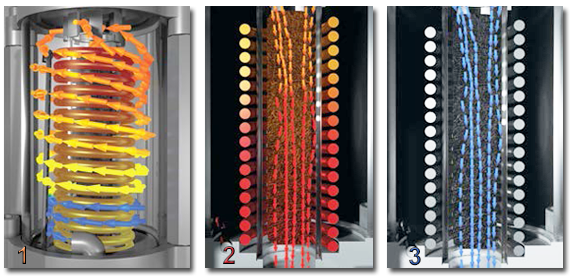

How Inductive-Convection Heating Works

The TF 2800’s patented Inductive-Convection Heating Technology provides ultimate thermal performance by its ability to instantly heat up and cool down the temperature of the air it delivers to the work.

1.) The air is first pre-heated in the outer heater chamber as it moves in a cyclonic fashion around the induction coil before it enters the inner chamber. 2.) After entering the inner chamber, the pre-heated air is then heated to target temperature through a highly efficient heat transfer process in an energized induction field. 3.) During active cooling, the induction coil is de-energized and the TF 2800 delivers fast, controlled, active cooling of the component and PCB directly through the nozzle, eliminating the risk of excessive intermetallic growth and yielding the highest quality solder joints.

Powerful, Energy Efficient Performance

The TF 2800’s Inductive-Convection Heating Technology delivers all the power you need to tackle the most challenging high thermal mass PCBs available today. Yet, its highly-efficient design does it with just a fraction of the power required by yesterday’s conventional heating technology.

Advanced Features

Ultra-High Precision Placement Capability

Ultra-High Precision Placement CapabilityNewly designed motorized reflow head is driven by an advanced stepper motor system which provides smooth, high precision, repeatable movement with no drift, allowing for soft landing of components and 28µm (.0011") placement accuracy.

High Sensitivity Vacuum Pick Assembly

High Sensitivity Vacuum Pick AssemblyNew Vacuum Pick design is more robust, utilizes an optical sensor, is counterweight balanced, and uses precision high temperature linear ball bearings for the highest sensitivity in placement and pick-up. Includes 7 Vacuum Picks.

PACE Exclusive Height Adjustable Bottom-Side Preheater

PACE Exclusive Height Adjustable Bottom-Side PreheaterAn array of 7 high powered IR emitters respond to high mass assemblies faster with 1900W of power. Preheater height is adjustable from standard position up to 38mm (1.5") closer to the PCB for the most challenging high thermal mass boards.

High-Definition Optical Alignment System

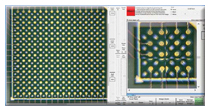

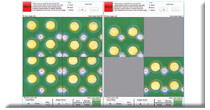

High-Definition Optical Alignment SystemAn automated Vision Overlay System uses a beam-splitting prism for simultaneous view of PCB pads and balls, high intensity LEDs for shadow-free lighting, and new high definition 1080p camera to easily align any component.

Crisp & Clear Images for Component Alignment

Crisp & Clear Images for Component AlignmentA high definition Vision Overlay System uses bright white LEDs with independent intensity control and up to 240x zoom capability to provide precise distinction of pads and solder ball or leads.

Quad-Field Imaging for Large/Fine Pitch BGA's

Quad-Field Imaging for Large/Fine Pitch BGA'sQuad-Field Imaging allows up to four corners of a large component (and its pads) to be viewed under high magnification, providing perfect alignment of outsized BGAs or fine-pitch QFPs.

Fourth Generation Software Suite

Newly designed Windows-based software provides a simple graphical interface with intuitive set-up and profiling, on-the-fly profile adjustment, unlimited profile storage and much more.

이미지 확대보기

PACE 페이스 TF2800 BGA SMD 리워크 시스템 8007-0583

비밀번호 인증

글 작성시 설정한 비밀번호를 입력해 주세요.

확인장바구니 담기

상품이 장바구니에 담겼습니다.

바로 확인하시겠습니까?